My brother’s VFR8 had appalling dive. It would dive so much it would bottom the fork very early and lock the front tyre. I don’t recall how much I reduced the air gap but it transformed the bike. From memory probably the worst dive I’ve experienced was on the FJ11 and 12.

Did you measure the air gap before emptying the oil out? Compare it to spec to ensure you have what you’re supposed to and then reduce it (put more oil in) by about 20-25% and try that.

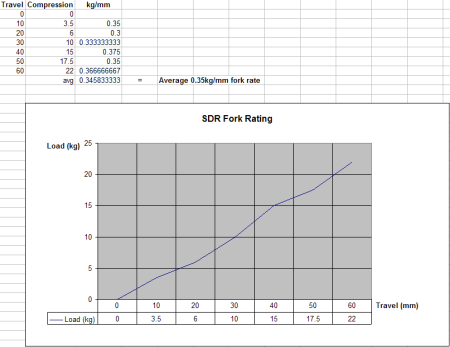

Are you able to measure the current spring rate? Simplest way is to:

- stand the fork on a bathroom scale with a tape measure alongside.

- Zero the scale then push down and read off the scale as a mate reads off every 10mm of compression.

- Then graph it – and average the kg/mm if it’s a linear spring.

If you can measure the height of the spring when the fork is extended (probably by adding and subtracting the fork cap height) then you can compress the spring fully and see how far you can go before it becomes coil-bound. If it’s more than the travel you have in the fork then you could cut a spacer (25mm conduit) to fill the difference but don’t go so far as to actually allow the spring to bind in use.